The Wild,

Wooden Wonder

![]()

The Wild,

|

|

Sequoia's sleek Falco F.8L qualifies as a classic.

by Dave Martin

This article appeared in the March 1986 Kitplanes. |

According to Webster, the word classic means, among other things, "traditional and enduring." The Sequoia Falco seems to qualify easily as a classic. Available now as a kit for the homebuilder, the Falco was designed more than 30 years ago by Italian Stelio Frati, and more than 100 of them were factory built in Italy. Manufactured Falcos are certified in the aerobatic category.

The Falco is testimony to a traditional and enduring airplane building material: wood. Modern adhesives and preservatives assure the endurance of a well-maintained wooden aircraft.

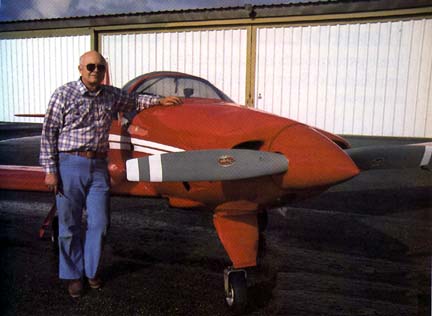

In addition to its sleek Italian styling, the Falco has a reputation for classic handling. With the help of Sequoia Aircraft president Alfred Scott, I tracked down builder Karl Hansen at northern California's Lincoln Municipal Airport for a close look at and some flying in his recently completed Falco. In every respect, the airplane is spectacular.

The Hansen Falco was built primarily by Karl, a retired U.S. Air Force pilot, with considerable help from son Stephen Hansen, a diagnostic radiologist who lives in Merced, California. Father and son are partners in the airplane.

Steve and Karl Hansen

The Falco, however, turned out to be a family project. Built mostly in Karl and Shirley Hansen's three-car garage at the Roseville, California, home, the project includes the efforts of another son, Jeff, and of Karl's brother, Don, a retired American Airlines 747 captain. Don says he took time off from cello practice to hold a lot of tools for Karl during the building process.

Stephen Hansen helped with the building when he could find time to get away from Roseville. His biggest contribution, however, was the instrument panel, avionics installation and all wiring. Stephen took the instrument panel home and did most of the installation and labeling plus much of the wiring there. Shirley says her son's work behind the instrument panel looks like it was done by a surgeon.

Steve works on the instrument panel

The length of time needed to construct a wooden airplane of this sophistication is a concern to many potential builders. Asked about the time required to complete his Falco, Karl Hansen noted the elapsed time was 23 months. He stopped trying to keep accurate track of hours spent, but he estimates he worked an average of 20 hours per week: 100 hours some weeks and nothing accomplished for a week or more at other times. Karl's total hours add up to about 2000, but that figure does not include "contemplation time" spent studying the plans and thinking about how the next steps would proceed. Also not computed are hours invested by Stephen and the others.

Despite the lack of a builder's manual when the Hansens were building, the Falco project was speeded greatly by the various Falco kits. Sequoia can supply 18 kits containing most of the plane's metal parts plus some instruments. These kits total $23,504 and do not include the Lycoming IO-320 B1A engine specified for the airplane.

Wood kits are available from Trimcraft Aero for just under $10,000, and a special internal-antenna package is available from Radio systems Technology for $120.

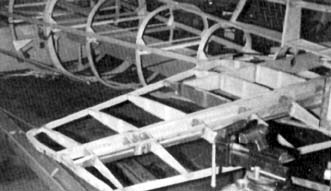

Wing ribs in the Trimcraft Aero kit come already built, and most of the wood parts are cut to shape, requiring trimming or fitting before installation. Alfred Scott is currently working on the Falco builder's manual, which is expected to shorten the building process by suggesting sequences and time-saving tips. Like many kit sellers, Sequoia Aircraft also publishes a builder/owner newsletter. Written by Scott, this newsletter and his F.8L Falco Product letter appear to pull no punches about Falco builders' questions, problems and solutions.

The Falco was a first aircraft project for the "Hansen aircraft company." Completeness of the kits, outstanding drawings and high-quality materials helped reduce the size of the project to manageable steps, Karl said. His scrapbook contains a complete photographic record of the building process; some of the pictures are shared here.

Hansen listed some of the tools he found especially useful. A handheld mini belt sander, spokeshave, industrial die grinder with one-inch sanding discs and high-speed steel burrs plus carbide-grit metal sanding blocks were high on Karl's list. He also recommended long carpenter's levels, lots of welder's clamps and sharp chisels for building a wooden airframe.

A special effort was made to keep the structure light. Don Hansen is credited with saving four to five pounds by pulling the staples used to hold pieces together during gluing.

After basic structures were assembled, epoxy varnish was applied to the inside of the plywood skins before covering. The entire airframe was covered with 1.4 ounce fiberglass cloth, requiring the plane to be turned over several times during this step. The tail from just aft of the cockpit was built separately from the rest of the fuselage, easing the job of turning the airplane (which included installed wings by this time) upside down. Even so, a block and tackle plus a good-sized group of people was needed for this operation.

Shirley Hansen passes the bubbly to Karl after his first flight in the Falco

The wing-to-fuselage fairing provided an area for innovation; fabrication details were missing from the drawings, Karl said. He glued blocks of 2-pound, closed-cell foam at the juncture and used templates supplied by Sequoia Aircraft. A curved, thin plywood spine provided a rigid trailing edge and an "aiming point" for the aft edge of the large fillet. Karl used an antique serrated cookie cutter to rough out the foam blocks to the contour described by the templates. The completed fairing is light, durable and looks great.

Early in the year, Karl Hansen knew that his goal of flying the Falco to Oshkosh '85 was going to be tough to meet. Son Stephen took time off to help, and brother Don became involved on a regular basis. The plane was almost finished in time, but not quite. Karl intended to complete first flights before painting, but the FAA inspector insisted that the fabric-covered control surfaces had to be painted with silver ultra-violet protective paint before the maiden hop. As a result, the first flight celebration, complete with sparkling apple juice supplied by Shirley, was too late to allow final finish, complete the FAA-assigned 25 hours of testing and fly to Oshkosh.

Looking back at it, Karl is philosophic, knowing the danger which a final frantic push to Oshkosh might have caused. The FAA inspector allowed a flight from Lincoln to Merced after 15 of the 25 test hours were flown. Karl and Stephen completed the test flights in a safe and leisurely manner. Overall, they are pleased with their progress. Theirs was the sixth kitbuilt Falco to fly. More than 400 sets of plans have been sold.

Finishing details including upholstery and paint were turned over to professionals. Ditzler Durethane was sprayed over an epoxy sealer. The results, both inside the cockpit and out, are gorgeous.

The Hansen Falco had logged about 36 hours before my visit. Karl and I analyzed Sacramento area forecasts daily for more than a week before picking a day between anticipated storms. The forecast looked a lot better than the actual weather upon arrival by commercial air in Sacramento. A forecast for improvement turned out to be correct, however.

Karl and Don Hansen were just finishing installation of the nosegear door as I arrived. The Falco was on jacks, and I helped adjust the up-gear switch which is supposed to turn the electric screwdriver motor off as everything is up and locked. As it turned out, we set the switch to do its job a bit too late. Raising the gear resulted in the landing-gear motor's circuit breaker popping at the end of the cycle. Back into the cowl with wrench and screwdriver for another try.

Karl wondered if the nosegear door would allow a higher cruise speed and if the extra drag with the door down on approach could be felt. He flew solo briefly to find out. At least initially, he could not detect any difference.

We followed the check flight with some air-to-air photography as Don Hansen and I flew in nephew Steve's Cessna 210. Karl flew the Falco alongside, and I motioned to Karl for small movements for my camera. Karl has retained formation flying skills since retiring from the Air Force; I found myself using wide-angle settings on the zoom lens.

Following all of this and some fuel added to the Falco, Karl invited me to climb into the left seat and to flying with him. No wing walk is provided on the Hansen Falco. A piece of carpet is used to avoid marring the wing surface when mounting up.

Climbing aboard without risking the upholstery is slightly complicated, but the expensive-car ambiance of the cockpit far overshadows this minor inconvenience.

Visibility from the cockpit is fighter like. Seats are slightly reclining and move fore and aft on rails. Toe brakes are installed on the left set of rudder pedals. The pilot-in-command therefore sits on the left side, moving the throttle with the right hand and applying stick pressure with the left hand. Probably the least-common controls layout, the controls nevertheless felt natural throughout our brief flight. (For those who want to fly with right hand on the stick, there is a $223 left-hand throttle kit available from Sequoia.)

Both disc wheel brakes and nose-wheel steering are powerful in the Hansen Falco, making taxiing easy. Karl said I would need some right rudder pressure during the takeoff roll, but little or no movement. He was right.

A Lycoming IO-320-BIA is the recommended power for Falcos, and this one provided a healthy shove into the seatback during takeoff acceleration. As expected, control pressures are light and there is little or no sense of stick or rudder movement. Adverse yaw is almost non-existent, even at a climb-out speed of 110 knots.

Karl said best climb speed is about 85 knots, but I climbed at 110 using "25-squared" power (25 inches manifold pressure and 2500 rpm) for excellent forward visibility instead of best rate. Climb with two of us aboard and about half fuel was a leisurely 900 fpm. Slowed to best climb speed and at full power later in the flight, the Falco elevated us at more than 1400 fpm.

Falco cruising flight is delightful. Power of 21 squared at 1700 feet yields 145 knots true airspeed (167 mph) with fuel flow of six gallons per hour, according to the fuel management panel.

The Falco is designed to be aerobatic, and one would expect it to roll fast. It does. A technique in these evaluations is to measure the time from a 45° bank one way to 45° the other, using full control deflection. In the case of the Falco, the roll reached the target opposite bank almost as soon as full stick deflection was achieved: less than two seconds. In fact, the steady-state roll rate of the Falco is said to be as high as 160° per second.

Yet the airplane is not twitchy; hands off the stick, it maintains the last attitude commanded. Karl Hansen summarizes it this way: "The Falco goes where you point it." The airplane does not feel "hot." Karl says Steve has had no trouble transitioning from the much heavier feel of his Cessna. like a few other airplanes, the Falco supports the illusion that flying requires no effort on the part of the pilot. Describing this in advance of my trip, Alfred Scott compared the handling of his plane to two other classics, the T-33 jet trainer and CAP 10 aerobatic airplane. With a bit of time in each, I can agree that the comparison is appropriate.

Karl Hansen

A stall series came next. Approached slowly, both clean and flaps-down stalls provide a heavy buffet several knots above minimum speed. Large triangular stall strips on the inboard leading edge of the wing may account for some of this warning. Rudder and aileron are powerful all the way to the stall, and neither wing tended to drop. (Before painting, Karl remembered, the right wing began to drop at the moment of stall.) Minimum speed was close to the numbers marked on the airspeed indicator: 58 knots clean and 53 knots with flaps down.

Like all slick airplanes, the Falco requires its pilot to plan ahead for descent. A few descending circles in the area permitted us to enter Lincoln's landing pattern at the right height and lower the landing gear (maximum gear extension speed is 108 knots). Little trim change was needed to transition to pattern speed. Karl selected partial flaps for me for this first approach. Eighty-five knots was a comfortable approach speed. Slowing a bit on final and a flare resulted in a fairly smooth touchdown with the nosewheel held slightly off the pavement.

Following takeoff and cleanup, we turned downwind for a final landing. Full flaps were selected this time, and a much-steeper, in-close approach was used. Steep approaches make short-field landings more practical and consistent, and some of the hot homebuilts all but eliminate short rollout by requiring fast, flat approaches. The Falco and its effective flaps are a refreshing contrast.

The steeper approach requires flaring more aggressively, and I almost under-did it this time. But with Karl's urging to raise the nose a bit more, the landing worked well, and the Falco deposited us on the airport ramp in style.

Despite this reviewer's usual reluctance to hand out rave notices, the Hansen's Falco certainly qualifies for one. Maybe the one nit-pick I am about to list will preserve my reputation, however.

The kit-Falco's sticks are shaped in such a way as to preclude the most comfortable pilot position: a light thumb-and-index-finger stick grip with an arm resting on a leg. That doesn't work because the stick is S-shaped like a helicopter cyclic, and the stick grip is too high. The portion of the stick below the grip is nearly horizontal, preventing a grasp there. As a result, I flew the Falco with my arm and elbow elevated, rather than resting on the leg.

Alfred Scott acknowledged that builders have noted the problem, and he intends to design a new stick. (His own Falco is a production version with different sticks.)

This is a mighty short list of gripes, but it was the best I could do with the Falco.

Shortly after I left, Karl performed some high-altitude speed checks to evaluate further the effect of the new nosegear door. His Falco airspeed indicator, incidentally, agrees closely with the family Cessna 210's speeds.

Climbing solo to a density altitude of 11,900 feet, Karl reported, the Falco achieved a true airspeed of 176 knots (202 mph) on 20.5 inches of manifold pressure at 2450 rpm, which yielded 166 knots (191 mph) for 6.7 gph fuel flow; 24.77 n.m. per gallon. Karl also noted a solo climb rate of 900 fpm passing through 10,000 feet on this flight.

A large NASA scoop on the right side of the engine cowl slightly pressurizes the fuel induction system, apparently. Hansen reports between 2 and 2.5 inches of manifold pressure above what would be expected at any altitude. During these early flights, the air filter was not installed. Alfred Scott says he expects a drop of about half an inch of manifold pressure with the filter in place.

Karl and Steve Hansen

What price all this glory? Karl and Shirley Hansen estimate they have $60,000 in their bright red Falco. The price, however, includes IFR instruments and King avionics: two KX-155 navcoms (one with glideslope), AT-150 transponder, Smith encoding altimeter, a KN-64 DME, electronic outside-air temperature gauge and the fuel-flow computer. (Flight instruments are not included in the Sequoia Aircraft package, but the company has arranged for the availability through other suppliers of unique Falco instruments such as a placarded airspeed indicator.)

Alfred Scott thinks a builder can get a Falco into the air for $47,000 which includes buying all the individual kits, a reconditioned IO-320 BIA engine and basic flight instruments. Avionics are not included in this estimate, and he acknowledges some builders may pour another $30,000 or so into that department. To get started, the full set of Falco plans and manuals sells for $400; an information package is available for $10.

Regardless of what it costs, there is little doubt that a conscientious craftsman with the time and money to build a Falco will end up with classic Italian styling, aerobatics with jet-trainer-like handling and affordable operations and maintenance costs. Flying doesn't get much better than that.

|

|