First Flight:

Bjoern Eriksen

![]()

First Flight:

|

|

by Jack Cox

|

This article appeared in the October 1993 Sport Aviation. |

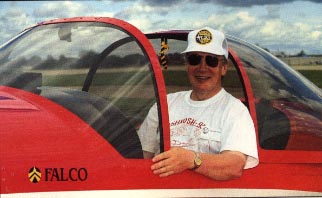

A couple of weeks before the start of Oshkosh '93 Jan Christie called to alert me that a Norwegian homebuilder was preparing to fly his Falco across the Atlantic to attend this year's EAA Conventions. A retired SAS captain living near Ft. Atkinson, WI, Jan was born in Norway so, naturally, was quite excited with the prospect of the first flight in a homebuilt between his native land and his adopted country. Moreover, he said, I had to see the Falco... the workmanship was "... at the level of the best we see at Oshkosh." Bjoern Eriksen was the builder's name and he was quite literally from the land of the midnight sun... a town called Bodoe, which, if I checked my atlas, I could find ont he coast of Norway just north of the Arctic Circle.

As always, Jan was right. The Falco turned out to be an exceptionally well built airplane... and woubld be named the Grand Champion Custom Built -- Plans aircraft at Oshkosh '93.

* * *

Bjoern Eriksen left Bodoe on Saturday, July 24... not really certain he would be allowed in the U.S. with the Falco. After months of painstaking preparation and dealing with the bureaucracies of five nations for the required permits, he had run headlong into the FAA's surprice moratorium on special flight authorizations (SFA) for foreign built aircraft. Flying his Falco to Oshkosh had been his dream for the nine and a half years it had taken to build it in his garate, however, so he had made the decision to fly as far as Canada on the change that the FAA might relent and allow him to fly on to Oshkosh. He was in contact with Ben Owen at EAA Headquarters and every effort was being made in his behalf.

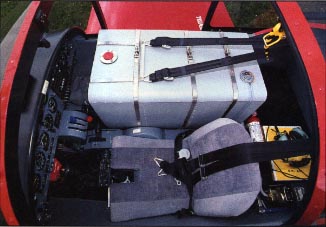

As he climbed out over the North Atlantic to his cruising altitude of 10,000 feet, Bjoern went through the mental checklist one final time. First and foremost, just at his right elbow was the beautifully crafted metal aux tank with 45 gallons of fuel to supplement the normal 42 gallons in his fuselage tanks. He smilled when he recalled his instructions to the person who had welded it for him: "This has to be done correctly. You must realize it will be seen by nearly a million people at Oshkosh." At his flight planned 160 knot (184 mph) true airspeed... at 20-21 inches and 2,350 rpm... the fuel provided a maximum endurance of about 12 hours. His longest leg, from Bodoe to Reykjavik, Iceland, would be about 6 hours with normal wind conditions, so he should not have to sweat fuel. Fromt eh outset this had been planned as a very conservative flight. All the flying would be during daylight hours and although he would be on IFR flight plans all the way, actual instrument flying would be avoided to the extent possible. With over 18,000 hours under his belt as a pilot for Norway's Wideroes Flyveselskap and a former instrument instructor, he was certainly qualified to handle any contingency, but his personal preference was to avoid single engine night and instrument flight.

Then there was the complete flight package he was able to borrow from the Norwegian Air Force, including a wet suit, HF radio and 22 pound survival kit. He also had a small bottle of oxygen to use in case he had to do brief climbs over weather.

Otherwise, he was depending totally on his smooth running 160 hp Lycoming IO-320 and an IFR panel with a standard stack of King avionics, a Century One wing leveler and a Trimble GPS, which he had mounted atop the glareshield.

The weather was good on the long leg to Iceland... in fact, to Bjoern's pleasant surprise, he actually had a slight tailwind most of the way. This is very unusual for an east to west flight across the often stormy North Atlantic. He spent the night in Reykjavik... and had the opportunity to visit a bit with Kermit Weeks and his crew who were waiting out some weather ahead on their flight to Oshkosh in the big Short Sunderland flying boat. They were having to make their flight VFR so were limited to flying between fronts.

The following morning he departed Iceland and spent most of four hours over ocean before landing in Greenland at Narssarssuag. It must cost the Danes a bundle to maintain the airport at that remote outpost, because they nicked Bjoern for landing and servicing fees totaling $600! As he departed for the North American continent, he vowed to bypass Greenland if at all possible on the return trip.

After another four hours, again mostly over the ocean, he landed at Goose Bay and called it a day. He went to bed that evening feeling pretty good about his Atlantic crossing. The airplane and its systems had performed flawlessly and the weather had been better than he dared dream it would be. Just a couple of times he had climbed to avoid icing in clouds and had used his oxygen for a few minutes, but most of the way it had been clear and he could see the vast Atlantic below him.

The next day, Monday, July 26, Bjorn doglegged to Moncton to get the aircraft inspection the Canadians require for Atlantic flights. He figured he might be in more of a hurry on the way home, so getting the inspection now would allow him to jump directly from Quebec to Goose Bay a week thence. At Moncton the last bureaucratic obstacle was finally cleared away. A fax from Ben Owen at EAA Headquarters revealed that the FAA had excluded homebuilts from its moratorium on foreign built aircraft, so he was free to proceed on to Oshkosh. That afternoon he flew to Quebec and remained there overnight.

The following morning the weather was IFR at Quebec and heavy thunderstorms were reported ahead near Montreal. The system was supposed to move through during the morning hours, however, so Bjoern decided to wait it out. He says he has to have a forecast for his destination of at least IFR minimums plus 500 feet before he will depart in any single engine airplane.

"I think IFR flying in a single engine airplane is primarily to have a smooth flight, especially if you are going a long distance. Then you are taken care of by ATC and you don't have to worry about all the TCA's. But I am very cautious about doing hard IFR in single engine aircraft... or, even worse, night flying in them. Over terrain such as we have in Norway and much of the world, for that matter, you have no options left if you have an engine failure at night."

This, EAAers, from a high time airline pilot who regularly flies in some, of the worst weather conditions in the world. Listen and take heed.

When he finally got away from Quebec later in the day, however, a time zone miscalculation between there and Wisconsin caused him to break his own night flying rule by a few minutes before landing at Green Bay. He arrived there about 45 minutes after official sunset, but thanks to the long summer twilight he wasn't in darkness very long. The following morning he made the short hop south to Oshkosh and achieved one of his life's goals when he touched down at aviation's Mecca in an airplane he had built with his own hands. All told, he had been in the air about 24 hours and had covered some 4,500 miles. He had flight planned for 23 hours, but that did not include the dogleg to Moncton which was about an additional hour. Excellent flight planning, superb navigation and a beneficent smile from the weather gods, one would have to say of Bjoern's journey to Oshkosh.

Once checked in and tied down, one of Bjoern's first tasks was to face my tape recorder and be interviewed for this article. Fortunately, he speaks good English because despite my years of association with Jan Christie and Norm Petersen, not a word of Scandinavian has entered my vocabulary. (But, then, they haven't picked up any Southern from me, either.)

Bjorn Eriksen is 51 and is a native of southern Norway. He has spent most of the past 30 years in the far north of the country, however, flying for a domestic airline, Wideroes Flyveselksap. Bitten by the flying bug at a tender age, he soloed a sailplane at 16 and transitioned to powerplanes shortly afterwards. He satisfied his military obligation by enlisting in the Norwegian Air Force where he served as a mechanic on F-86's. During that time he continued his own flying, progressing through his Private and Commercial licenses. To build time, he towed gliders, flew charter and anything else he could log. Eventually, his qualifications were such that he was hired by Wideroes to fly Norseman's among the islands and jords of far northern Norway. After three years, however, he left to get his instrument rating and ATP, repairing sailplanes and rebuilding lightplanes to help pay for the training. His first job as an ATP was with a company that flew freight throughout Europe for SAS, and among the aircraft he piloted was the venerable Curtiss C-46 Commando.

In the late 1960's the Norwegian government began building a network of small airports along its extremely rugged coastline to help reduce the isolation of people living in these areas, especially above the Arctic Circle. Most of the runways were just 800 meters (2,624 ft.) long, so STOL aircraft would be necessary to operate from them. Wideroes Flyveselksap won the contract to service the network and initially equipped itself with deHavilland Twin Otters. Most of its personnel were seaplane pilots without instrument ratings, so Bjoern was asked to come back with the company to serve as an instrument instructor. He took the job and after eventually getting everyone rated, began flying the line himself. 4-engine deHavilland Dash 7's were added to the small fleet after about 10 years and Bjoern switched to them. More recently, twin engine Dash 8's entered service with Wideroes and that is what he flies today. He, his wife, Torill, and their son, Morten, live in Bodoe, which is a base of operations for the airline. The area is nice in summer, he says, but very windy in winter, with 30 to 40 knots common and 70 to 80 knots and sometimes even 100 knots not at all unusual. Wideroes continues to fly on schedule, nevertheless, he says!

Bjoern's Falco

Bjorn fell in love with the Falco when it was introduced to the

world in 1955 by its designer, Stelio Frati. Just 14 at the time,

it would be many years before he could do anything but dream about

owning one... and even after becoming an airline pilot, the few

production models that occasionally came up for sale in Europe

were always out of his reach financially. Finally, however, when

Sequoia Aircraft made plans and components available in 1980,

he saw his way clear to owning a Falco. He purchased his plans

the following year and began a very systematic process that would

see his airplane completed some nine and a half years later...

and after about 9,000 hours of construction time.

U.S. builders can cut that amount of building time considerably by buying the finished airframe components offered by Sequoia Aircraft, but that option was not open to Bjoern. The Norwegian aviation authorities allowed him to purchase the landing gear, engine mount, metal fittings and such, but made him do all the woodwork himself.

Bjorn says that he knew from past experience that in order to keep himself on a project, it needed to be readily accessible. It is no small task to get to a remote shop and back home when you live above the Arctic Circle, and all too easy to find an excuse to stay at home where it's warm. He therefore banished his wife's car to the driveway for a decade and remodeled their garage as his Falcowerks. Significantly, the interior space measured just 8 x 3 meters, or 26 x 9 feet, which presented some very interesting problems. Before he cut the first piece of spruce, Bjoern worked out an elaborate plan for building the airplane that involved work space clearances down to fractions of an inch. Crucial to the procedure was the sequence in which the various components would be built and mated... which dictated frequent gatherings of friends to help walk some part outside, turn it around or upside down, then carefully ease it back into the shop. When the one piece wing was built, a temporary extension had to be built onto the garage.

The most jarring insight into just what he was getting himself into came when Bjorn began ordering materials. Norway has a 24% tax on everything imported, and that is on top of the exchange rate and high freight costs. The result is about double the cost we are accustomed to paying here in the U.S. -- for everything! All told, Bjorn says he has about $130,000 in his Falco... just in the things he had to purchase. The only way he was able to afford the airplane, he says, was by selling some real estate he had inherited.

And we think we have problems here in the U.S.!

One of his procurement exercises turned out to be quite amusing as well as frustrating. Norway is a densely forested country, so when Bjoern went down to the local customs office to pick up his order of spruce from a supplier in England, the officials could not figure for the life of them why anyone would be paying a very substantial amount of money to import... wood! Bjoern still laughs uproariously when he recalls the incident.

"They thought I had gone completely mad!"

The spruce from the English supplier, incidentally, was all certified, with an official stamp on every piece. Local suppliers were able to provide aircraft grade Finnish plywood, but it had to be ordered about six months ahead of the date needed.

Everything that went into the Falco was new, including the engine, prop, instruments and avionics. Bjoern attempted to reduce the enormous price of the 160 hp Lycoming IO-320-BlA he would use by purchasing it directly from Lycoming, but was told he would have to go through the Norwegian dealer... and pay the middleman, of course. He says he got a good price through the dealer, but it was still extremely high. He was able to buy a new Hartzell CS prop more reasonably through Sequoia Aircraft, but there was no way around the duty and freight charges. Instruments and the King avionics came similarly dear.

Bjoern spent the first year of the project building all the ribs... the second year on the laminated fuselage frames... and the third on the wing and tail spars. Next came the assembly and skinning of the tail surfaces, and, finally, the fuselage. Here, the limitations of his building space caused him to deviate from the sequence most builders follow when constructing a Falco. He built the fuselage in its entirety, right up to the point of painting, including the installation of the canopy, the engine and cowling.

Then he took his jigsaw and cut it in half just behind the canopy.

With the engine removed, the forward half of the fuselage would just fit crossways in his garage shop, allowing the wing to be built onto it. This would be the most difficult job Bjoern would encounter, largely because he did not have room for conventional jigging. It also meant he had to build the wing in the horizontal position rather than vertically, as most builders do. All this created a need for an exceptionally accurate baseline for the various measurements, and his solution was the use of a transit. It was a time consuming process, he recalls, but it allowed him to build a straight airframe in his cramped working space.

Homebuilders always lament the fact that the obligations of everyday living limit the time they have to build, and, especially, to spend long, consecutive hours on particular tasks. Bjoern had a leg up on most builders in this respect because of his work schedule with Wideroes. He works for a week, then has a week off. On his weeks off, he put in 8:00 a.m. to 5:00 p.m. days on the Falco just as if it were a regular job, then spent evenings with his family.

"This way, my wife and the boy did not notice the building so much. At the end when I moved the entire project to the airport, they were affected by my absence, but the aircraft took shape fast enough that they were able to live with it. It is easier when the end is in sight."

Some incidentals along the way included the fact that Bjoern used Aerolite glue for all the small parts and a European epoxy for the jobs that needed some working time. He put a great deal of effort into getting the plywood skin on as straight as he possibly could and used a filler he made up out of epoxy and microballoons to smooth out the few little waves he could not avoid.

When the woodwork was finally completed, he applied a thin layer of epoxy on the entire surface of the wing, then smoothed a layer of very thin fiberglass cloth onto it... the silk-like material used on model airplanes. The cloth was carefully worked into the epoxy and paper towels were used to soak up the excess that oozed up through the weave. The result was a surface that could be easily sanded smooth and made ready for painting. There never was any question about the color that would be used... it would be red with white trim... but the shade of red was the subject of literally years of research. Bjorn became hypersensitive to the color during the decade he was building his Falco, taking note of everything he saw that was red. He finally decided the best place to look was cars because there were so many shades of red on them and because they were large enough to provide a good idea of how a color would look on the airplane. Eventually, he saw an early 1980's Volkswagen red that struck his fancy, and that's what he eventually used. It is an acrylic enamel made in Germany and is very easy to touch up, he says. The garage/workshop was really a part of the inside of the Eriksen home, sharing the heating system and ventilation, so there was no thought of turning it into a paint booth. Instead, the airframe was transported to a car painting shop and shot there by a professional. The white trim and "LN-LCA" on each side of the fuselage are adhesive backed plastic film.

The IFR panel was designed and built up by Bjoern, including the wiring. His company allowed him to take a desk in the avionics shop and he spent 2-1/2 months on the wiring. He also did all the drawings for the wiring and had the shop foreman check them out. All the antennas except for the ADF and transponder are inside the airframe... with the proper spacing between them to eliminate interference. A large patch of wire mesh was glued to the skin to serve as a ground plane, and copper tape was used to create most of the antennas. The HF antenna was of the greatest initial concern to Bjorn because of the length it needed to be. He ended up running a copper wire the complete length of the rear face of the rear spar... and it worked like a charm on the flights to and from the U.S. He never missed a position report, and was able to talk to his home base back in Bodos a good bit of the time.

The Falco was taken to the Wideroes hangar for final assembly and checkout of all systems, which took the better part of a year and a half. When finally completed, the airplane had an empty weight of 1,256 pounds (570 kilos), which is almost exactly the number builders are urged to shoot for. Bjoern says he was very conscious of weight throughout the building process, especially in the finishing and painting stage where so many pounds are picked up on most homebuilt projects.

Bjorn flew the airplane for the first time on February 22, 1991... and it was, according to Sequoia Aircraft, the 29th Sequoia Falco to fly. A very thorough and professional flight test program was carried out in succeeding weeks and LN-LCA proved to be a straight airplane that required no tweaking to make it fly hands off. It gets off in under 1,000 feet, and Bjoern climbs it at 100/110 knots (115/126 mph) for best cooling. The best climb is at 90 knots (103 mph) and temperatures never reach the red line at that speed, but he likes to be easier on the engine. At 2525 rpm and 100/110 knots the rate of climb is about 1,300 fpm. He has been to 15,000 ft. and the airplane was still climbing at 300 fpm. Cruise at 10,000 ft. is 170 knots (195 mph) true at 65%... but on the flight to and from the U.S. the Lycoming was throttled back a little for better fuel economy.

Interestingly, Bjoern says that when he waxes the airplane, it picks up 5 knots at cruise, and loses 10 knots when he flies in rain... which must mean that like many of the composite airplanes, his perfectly smooth Falco is enjoying some natural laminar flow when it is clean and dry.

LN-LCA had been flown 200 hours when Bjoern set out across the Atlantic and was completely de-bugged by that time. As a result, no problems were encountered in either of the Atlantic crossings.

Early in the final week of Oshkosh, Bjorn's wife, Torill, flew by airline to Oshkosh and was with him on Wednesday night when he was called to the stage at the Theater in the Woods to receive EAA's 1993 Grand Champion -- Plans award for homebuilt aircraft. He and his Falco were our first international Grand Champions, the first Grand Champions to fly the Atlantic to get their awards, the first from Norway and the first from above the Arctic Circle. Bjoern is proud to be a representative of his country and Norway is certainly proud of his accomplishment, but the quality of his work on his Falco transcends national boundaries. The airplane is a grand champion in any arena and in any time frame. Sport aviation is about as truly international as any of the world's endeavors, and all of us everywhere can be proud of this man and his Falco.

Bjoern headed back to Norway on Thursday, August 5, leaving Torill in the good hands of the Jan Christies, who drove her to Chicago to catch her plane home. He stopped in Sault Ste. Marie, Ontario, for customs, then flew on to Toronto to end the first day's flying. On Friday, he flew to Quebec and then on to Goose Bay where he would would remain on Saturday to allow bad weather in Greenland and Iceland to move out. He took advantage of the layover to do a very thorough 50 hour check on the airplane... and to relax a bit.

On Sunday morning, the forecast was good out over the North Atlantic, so he filed direct to Iceland. To his displeasure, however, the promised tailwind pooped out and he had to land at Narssarssuag. That meant another $600 landing fee and the expenses of an overnight stay, but an unnecessary risk was avoided.

On Monday, Bjorn had an uneventful flight to Reykjavik and

after landing was met by an Icelandic television crew that taped

an interview with him. That evening he was able to watch himself

on TV... and just begin to grasp the new celebrity status he had

acquired.

On Tuesday, August 10, the weather along his proposed GPS direct

route to Bodoe was not good, so after discussion with forecasters

in both Iceland and Bergen, Norway, Bjoern decided to skirt the

southern edge of the storm and land at Aalesund on the southwest

coast of Norway. The weather was excellent for his arrival back

on his native soil at 6:00 p.m. local time... and we were aware

at EAA Headquarters within the half hour of his safe arrival.

I still don't know how he did it... possibly it was through his

old SAS connections... but Jan Christie was on the phone with

Aalesund controllers or weather personnel relaying his congratulations

to Bjoern as he was landing. Jan then immediately phoned us at

Oshkosh with the good news. Later in the day (U.S. Central Time),

we would also learn Bjoern was safely home in Bodoe... thanks

to the miracles of modern communication!

After clearing customs and being interviewed by local papers, Bjoern filed his first VFR flight plan of the entire trip and took off for the two and a half hour flight up the Norwegian coast to Bodoe... and home. It was late in the evening as he sped over the awesome panorama of ocean, fjords and mountains, but since the sun does not sink below the horizon in those latitudes in summer, Bjoern was treated to the glories of a perpetual sunset all the way to Bodoe. As he would write shortly afterwards:

"I'm used to this scenery, but even for me this was a fantastic flight... ending two fantastic weeks!"

|

|