Thinning West System Epoxy

![]()

Thinning West System Epoxy |

|

by Brian Knight

|

This article appeared in the Fall 1999 issue of Epoxyworks, published by Gougeon Brothers, manufacturers of the West System epoxies. Our thanks to Gougeon for permission to publish this in the December 1999 Falco Builders Letter. For more information on West System epoxies, please visit the Gougeon Brothers website. |

A question frequently posed to our technical staff is "can I thin West System epoxy so it will flow or penetrate better?" The answer to that question is "yes, but not without consequences." Many of the advantages of thinning epoxy are offset by disadvantages in other areas of epoxy performance.

Thinning epoxy means lowering its viscosity. Low viscosity epoxy flows better, is easier to roll or brush, saturates fiberglass fabric quickly, and penetrates more deeply and more easily into porous surfaces like partially rotted wood. There are two methods of temporarily thinning epoxy. One is to heat the mixture and the other is to add solvent to the mix. The goal of both methods is to reduce the epoxy's viscosity. This article explains what happens to West System epoxy when it is thinned either by heating the components or adding solvent to the mixture.

Through knowledge gained from our comprehensive test programs and from 30 years of practical experience, we have learned that epoxy formulation is a balancing act. When one characteristic is altered-e.g. changing handling attributes by adding a volatile solvent-other characteristics like moisture resistance and strength are also changed. Our chemists formulate a well balanced, versatile epoxy that provides excellent structural strength and moisture resistance. If you elect to modify it, you become an epoxy formulator and need to understand the effects of your changes. Armed with the information in this article, you can decide if thinning epoxy is worth the tradeoff in performance.

Is thinning necessary?

There is a perception that epoxy needs to penetrate deeply into

wood to be effective. Sometimes this is true, but most of the

time it is not. Some common misconceptions are that deep penetration

of epoxy 1) makes rotted wood as strong as new, 2) increases adhesion,

and 3) makes wood more waterproof. The following is a brief discussion

of these points.

1) Rotted wood impregnated with epoxy does not make the damaged wood as good as new. Deep penetration of epoxy into rotted wood will make the wood hard but it will not restore its original strength. This is not important if the rotted material is non-load bearing. A rotted door threshold does not need to be strong, just hard. However, when the wood fiber is damaged, wood loses its ability to carry loads and unless the fiber is replaced, it will not regain its full strength. A rotted deck beam or sailboat mast needs more than epoxy consolidation to return the wood to its original load carrying capacity.

2) Adhesion in all but the highest density wood is not enhanced by deep penetration of the glue into the wood. Research performed at the Forest Products Laboratory showed that adhesion to birch was increased slightly by using thinned epoxy. In lower density wood species like Sitka spruce or Douglas fir, the weak link is the cross grain strength of the wood. It does not matter if the epoxy penetrates l/4" into the wood or 0.005". The strength of the wood, the amount of surface area and the adhesive ability of the glue determine the strength of a glue joint. Most types of wood glue do not penetrate deeply, yet, if used properly, they can exceed the grain strength. Epoxy is no exception.

3) Water resistance of a piece of wood is not enhanced by deep penetration. Wrapping wood in plastic makes a pretty good waterproof seal without any penetration at all. Likewise, an epoxy coating on the surface is more water-resistant than a thinned epoxy coating that has penetrated deeply into the wood because, in most instances, the epoxy thinned with solvent is porous.

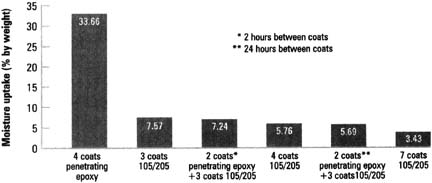

Figure1. MEE of various combinations of thinned and unthinned

epoxy at six weeks exposure to 100% humidity.

The USDA Forest Products Laboratory developed the Moisture Exclusion Effectiveness (MEE) test. It is a measure of how much moisture is absorbed by wood when it is continuously exposed to 100% humidity. Higher numbers mean the wood has absorbed more moisture while lower numbers indicate less moisture is absorbed. You can see that epoxy with solvent added is not nearly as moisture resistant as un-thinned epoxy (Figure 1). However, if you need an epoxy coated surface that is less of a vapor barrier, thinning West System epoxy with solvent is a valid way to achieve this.

Thinning epoxy with heat

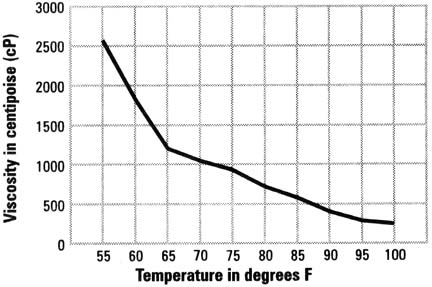

Heating the resin/hardener components and then mixing them together

results in a thinned epoxy mixture that, when cured, retains all

the characteristics of epoxy cured at room temperature. The viscosity

of epoxy is very sensitive to changes in temperature, and warming

the components (resin and hardener) and/or the substrate substantially

lowers its viscosity (Figure 2).

Figure 2. Viscosity of 105 resin vs temperature. Resin viscosity

is reduced as the temperature is raised.

With wood, the best method of thinning epoxy with heat is to warm the wood and have the resin and hardener at room temperature. Mix the components and apply the mixture to the warm wood surface. Remove the heat source just before the epoxy is applied. When the epoxy mixture comes in contact with the warm wood, it gets warm and its viscosity becomes lower. As the temperature of the wood falls, the thin epoxy is drawn in deeply before it begins to gel. By heating the substrate instead of the components, you get the best of both worlds-low viscosity epoxy on the work surface and longer working time in the mixing pot.

Potential Problems

Thinning epoxy with heat can create problems, however. Warm epoxy

cures much more quickly than you may be accustomed to. Have things

organized before you mix the resin and hardener and move quickly.

Use one of the slower hardeners-206, 207, or 209-to increase the

working time.

How warm is warm? You should be able to comfortably touch the substrate or the component containers when they are appropriately warmed-about 115°F maximum. Excessive heat will cause the epoxy to harden too fast, especially in thick applications. Very rapid cure will overheat the epoxy. If smoke rises from the curing epoxy, it is likely the epoxy is damaged and should be replaced.

Thinning epoxy with solvent

Adding solvent is a quick, simple method of thinning epoxy, but

unlike using heat to thin it, the strength and moisture resistance

of the cured epoxy are drastically affected. Below are some of

the effects adding solvent has on West System epoxy. While there

are a large number of chemicals available to thin epoxy, we selected

acetone, lacquer thinner and denatured alcohol for this discussion

because they are commonly available and do a good job of reducing

viscosity. Additionally, these solvents evaporate quickly and

are less likely to be trapped in the cured epoxy-an important

characteristic. For a variety of reasons, fast evaporating lacquer

thinner appears to be more appropriate for thinning purposes than

acetone or alcohol.

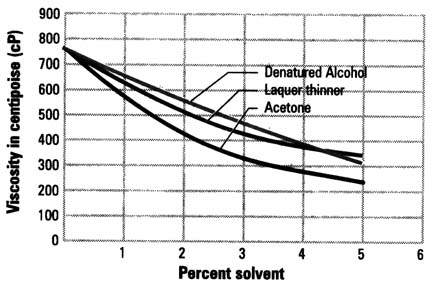

Figure 3. Viscosity of 105/206 epoxy vs percent of solvent added.

· Adding a small amount of one of these solvents has a significant effect on the viscosity of the epoxy. For example, adding 5% lacquer thinner makes about a 60% reduction in viscosity (Figure 3).

Figure 4. Compressive strength of 105/205 epoxy vs percent of solvent added.· Adding 5% lacquer thinner to epoxy reduces the epoxy's compressive strength by 35%-a big hit in the mechanical properties of West System epoxy (Figure 4). The addition of more than 5% solvent results in an excessively flexible cured-material. Thinning epoxy with solvent causes enough loss of strength that we (and most other reputable epoxy formulators) cannot recommend using it as a structural adhesive.

· Adding a volatile solvent extends the pot life and cure time of epoxy and jeopardizes the reliability and predictability of cure. Additionally, with slow rate of cure, it takes longer before work can be sanded.

· Adding volatile solvent may cause shrinkage of the cured epoxy. Applying thinned epoxy in large, confined areas (like consolidating a large pocket of rotted wood) is likely to trap some of the solvent. In thick applications, the epoxy cures very quickly and not all of the solvent has time to evaporate before the epoxy hardens. Over time, the solvent works its way out and as this happens, the cured epoxy shrinks and in many instances cracks.

Shrinkage also causes print-through. You may have a surface sanded smooth only to have the resin shrink. This shrinkage often reveals the texture of the substrate. Shrinkage can continue to be a problem until all the trapped solvent works its way out of the cured epoxy.

· Adding solvents, especially acetone, alters the color of the cured epoxy. While the effects are not immediate, adding acetone to epoxy causes the color to change from slightly amber to very dark amber.

· Adding solvent results in a temporary reduction in viscosity. Volatile solvents evaporate quickly as they are agitated during brushing or rolling, causing the viscosity to continually change as time passes.

· Adding solvent to epoxy may damage the substrate. Many materials (Styrofoam for example) are not attacked by epoxy but may be attacked by the solvent used to thin the epoxy. Be certain to test the substrate with the solvent before using it to thin the epoxy.

· Adding volatile solvent to West System epoxy has some adverse health and safety effects. West System epoxy components are nonflammable but the chance of fire or explosion goes up in proportion to the amount of solvent you add. Also, the vapors of many volatile solvents are hazardous to your health and proper ventilation is mandatory to prevent inhaling harmful quantities of them.

· Adding volatile solvent to epoxy which is then applied as a coating may cause problems with various regulatory agencies. If your business is inspected for air quality, adding volatile solvents to West System epoxy may make your business noncompliant.

· Adding solvent to epoxy to enhance fiberglass wet-out will result in more "drain out" of the resin on a vertical surface. The fabric will wet-out quickly but it may become resin starved when too much epoxy runs out of the fabric.

Does thinning epoxy make sense? In some situations, thinning is appropriate. In others, it is not. We feel that in most circumstances using heat to thin epoxy is preferred to using solvents. As long as the epoxy does not overheat during cure, the full physical characteristics of the cured epoxy remain. Adding solvent is a quick, simple method of thinning epoxy, but the strength and moisture resistance of the cured epoxy are signiflcantly reduced.

We will continue to research this subject and publish our findings in Epoxyworks.

|

|