Gearbox

![]()

Gearbox |

|

In the past, the P/N 520 gearbox has been made as a casting of 356T6 aluminum, then machined for the bearing bore and assembled with bearings, shafts and gears. We are now making this part as a machined part from a single block of 6061T6 aluminum. This is only possible with the machining centers that are now available. So let's show you this whole process. |

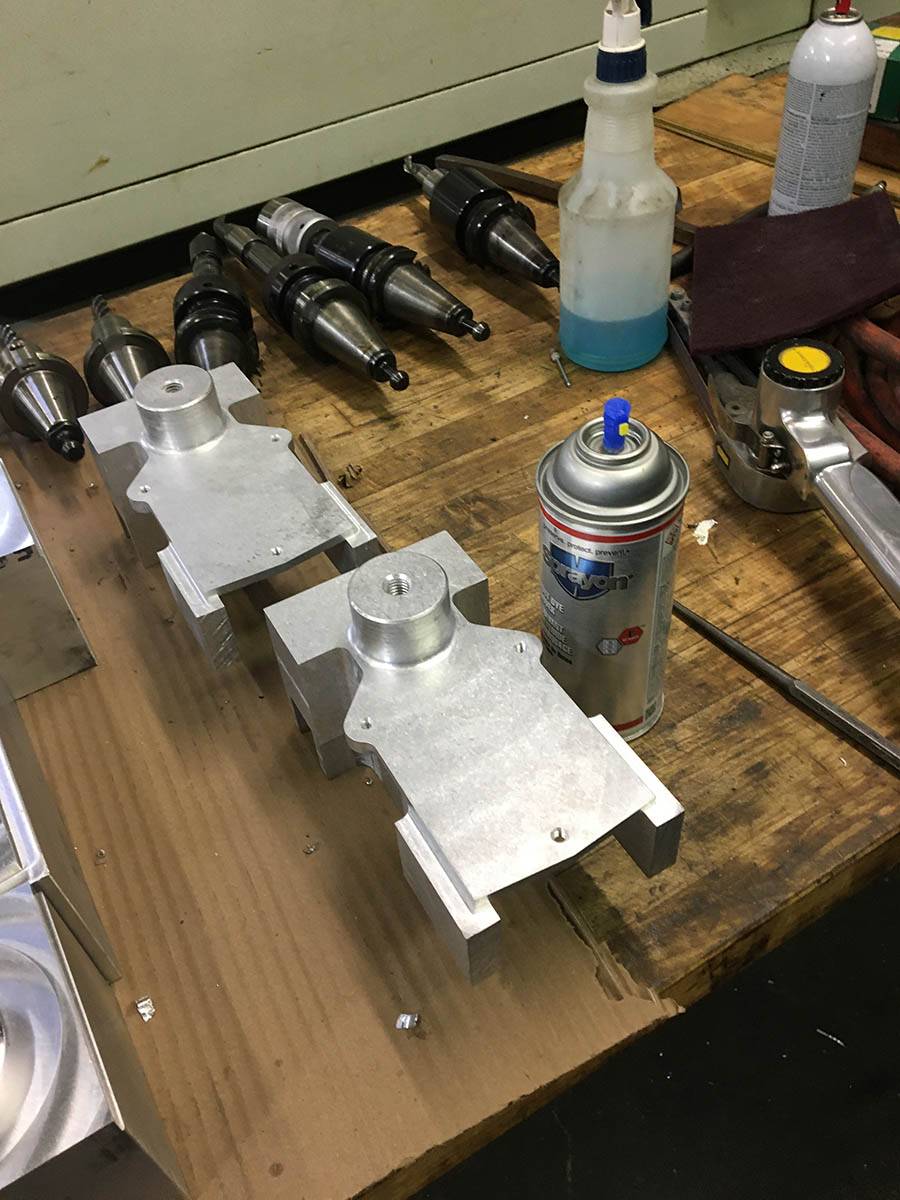

We start with the solid blocks. These are castings which are dead soft, then forged into the blocks you see here with a giant drop hammer. This gives the shape of the blocks and work-hardens the aluminum to the T6 condition. Now it's a very strong block of aluminum without any voids or imperfections. |

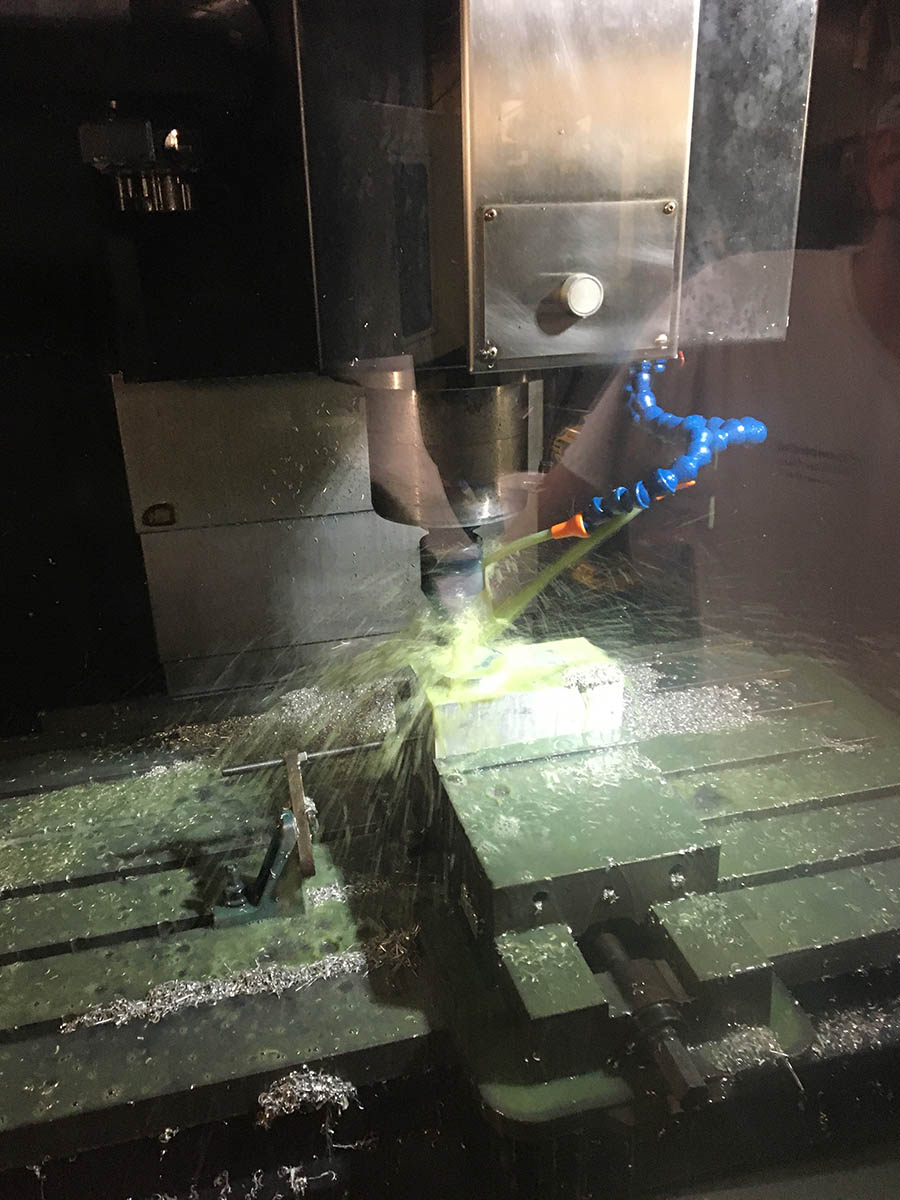

Which then goes into the machining center. |

... and the first face is machined. |

Which then completes the first stage. |

Now we have a fixture to hold this part for the next step of machining. |

And here we go hogging this up. |

... which gives up this. |

Note that the holes are drilled and tapped to secure this to the fixture. |

Here's the fixure in the machining center. |

Now it gets milled into shape and with bearing bores. |

It's not enough to machine the bearing bores. The cutters leave marks, so now we use a roller burnisher that smooths the inner bores to a polished surface. |

There are some holes to drill. |

Giving us parts that look like this. |

Let's check that the retraction motor assembly fits, and of course it does. |

Parts will be available from Gunder soon. There is a limited supply, so get your order in. |

|

|