Craig Bransfield

Skinning

![]()

Craig Bransfield

|

|

|

From "Construction Notes" Falco Builders Letter, March 1990 |

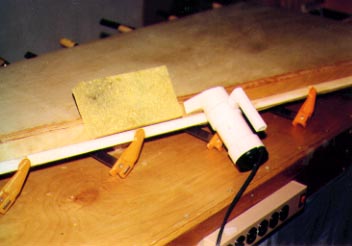

Craig Bransfield has come up with some minor variations and refinements for skinning the stabilizer and bending the skin around the leading edge. He used the Karl Hansen method of gluing a 20x20 strip of scrap wood to the plywood (see Chapter 10, Figure 11 of the construction manual) but did not use nails and rubber bands.

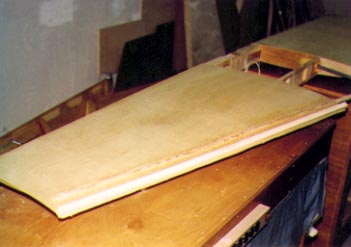

Craig glued the stabilizer skin on dry and used nailing strips made of 1/4" plywood. These covered all of the ribs and spars. At the leading edge, he used two 7mm-wide strips. He installed the skin dry and glued to skin to only a portion of the leading edge strip-just that portion that was flat enough that the skin would lay down on when dry. Craig put masking tape on rest of the leading edge strip or the undersurface of the overhanging skin to keep the glue from "contaminating" those areas. With the skin glued down dry, there was no tendency for distortion at the aft edge of the leading edge strip.

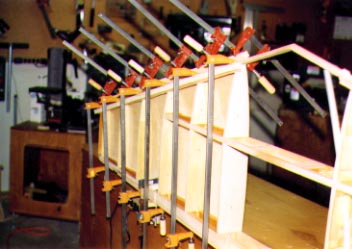

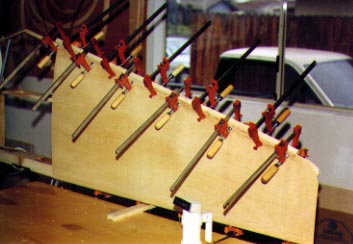

When the glue was dry, Craig removed all nailing strips except for the two 7mm-wide strips, and he removed the masking tape. It was now time to bend the skin around the leading edge strip. Craig used bar clamps (2 each of 18", 24" and 36") to pull the skin around. The clamps were located to take advantage of the strength of the installed ribs, but there is actually relatively little force requred during bending. Craig found the biggest problem was forgetting to tighten the clamps evenly and having them fall off.

Now comes the real neat-o part of the operation, bending the skin with a clothes steamer. Craig says, "When one of us decides to open up a Falco factory, this is the job I want! Using my little ultra-cheap clothes steamer and a wet sponge, I went slowly back and forth across the leading edge, staying long enough in each spot to raise the wood temperature all the way through and allow the steam to penetrate the wood. This causes the plywood to quickly 'stress-relieve', so you can tighten up the clamps a little and pass by again. Five or six passes in 30 minutes was all it took to lay the skin all the way around to the other side of the stabilizer-and with no pre-soaking! All the heat, moisture and bending stress are concentrated exactly where they should be. This task is unbelievably pleasant-the aroma of the heated wood fills the air, absolute control is maintained and not a bead of sweat is raised!"

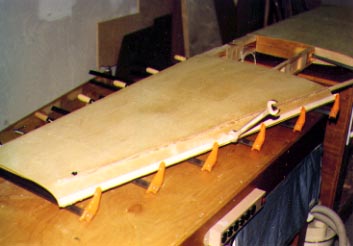

Craig says that about 40-50% of the bend will spring back when the clamps are released but this was not a problem. Craig concentrated the bend at the leading edge a bit more by clamping a caul strip to pinch the bend a slight additional amount and the 7mm-strips provided a surface to clamp to.

The same clamping system was used during leading edge glue-down and the caul strip kept the skin from puckering out from the leading edge strip. Since the bottom skin applied is to be scarfed to receive the top skin which will be similarly wrapped around the leading edge, Craig only glued the skin down as far as the stabilizer centerline on the L.E. strip.