Upholstery

![]()

Upholstery |

|

|

August 1998 |

The new Crutchfield catalgue lists for sale something called Dynamat, which automotive hi-fi freaks apparently put on the inside of their car's various panels to dampen noise. It's self-adhesive, apparently with the help of a hair dryer, which the photo shows. Said to reduce noise "by 3dB or more, effectively doubling your amplifier power." Dunno how much it weighs, but it comes in standard and "super," the latter thicker and for high-temperature applications such as firewalls. They sell it in quantities from 4.33 square feet ($20) to 39 square feet ($150). Their customer-service number for queries is 800 955-9091, if any Falco builders are interested in looking into this as a sound dampener for the airframe.

Personally, I think "soundproofing" a Falco is an oxymoron of some sort, and the money should be put into the best possible ANR headset rather than inactive damping of any sort.

Stephan Wilkinson

|

From "Construction Notes" Falco Builders Letter, September 1993 |

Cecil Rives is finishing up his Falco and hopes to have it in the air in a few weeks. In doing the upholstery, he made a mistake that he would like to warn others about. He covered the glareshield and the area immediately in front of it with one piece of leather. This means that the glareshield cannot be removed separately, which makes it very difficult to remove the fuel tank.

|

From "Construction Notes" Falco Builders Letter, September 1993 |

|

|

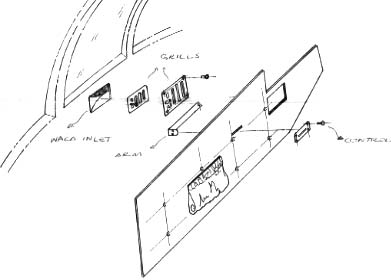

Marcelo Bellodi's fresh air vent.

|

From "Construction Notes" Falco Builders Letter, June 1989 If you have been working on your upholstery, then you already know that fire-resistant foam padding is difficult to find. Steve Wilkinson saw an announcement of a source in Flying. He sent us a sample and also advises that he bought too much, so if you need some, give Steve a call at (914) 534-7601. Now, I'll just turn the 'phone over the Steve. Alfred Scott |

The smelly sample enclosed is a piece of the upholstry padding I bought from Chestnut Ridge Foam. No auto body or trim shop I talked to around here knew anything about "fire-resistant foam," and they barely knew anything more than that they stuffed some kinda soft stuff in behind the upholstery when they were installing a headliner or a vinyl top. What it was, how thick it was, where they got it... all great mysteries, and they apparently just threw in whatever was around the shop that day.

So I'm delighted to have found this material, even though it's a bit thicker and heavier than optimum, being 3/8", but it is made specifically for aircraft applications and is fire-resistant enough to come with a piece of paper that certifies it as meeting FAR 25.853(b)-the FAA's "blowtorch test." The 3/8" thickness is the thinnest they supply; there is a 1/4" foam, but it's considerably stiffer and not recommended for padding applications.

One nice thing about this stuff is that it comes with its own thin fabric backing, so you can sew this directly to the upholstery itself rather than using some kind of muslin backing to keep stitches from pulling through the foam, and you can then glue the foam-and-upholstery sandwich directly to the thin plywood (or whatever) upholstery-bearing panels.

The stuff is called LS-200(C) and comes in sheets each a yard wide and 60" long. They're $10.93 a sheet-less than 75 cents a square foot. Chestnut Ridge Foam is at Box 781, Latrobe, Pennsylvania 15650-412 537-9003. The company is perfectly willing to supply small quantities-I bought five sheets' worth-but they do ship COD (no credit-card orders) and are accustomed enough to dealing with OEMs and professionals that when my shipment arrived, the COD instructions were that nothing but a "company check" was acceptable.

UPS had to come back the next day when I had company cash, which was also acceptable.

Steve Wilkinson

|

From "Construction Notes" Falco Builders Letter, March 1988 |

Of the four seat-track sets included with the seats-and-equipment kit that Susan bought me for Christmas-whatta wife!-I was able to mix-and-match two sets (one seat's worth) into free-sliding units. The other two sets were virtually immovable. After spending an hour banging and prying away at one of the lower tracks-the track within which the piece attached to the seat bottom slides-I gave up trying to widen it slightly. They're too tough.

What did work, however, was a liberal dose of Permatex valve-grinding compound-it's a fairly coarse paste, comes in a tube, available in any good auto-parts store-and slowly working the sliders back and forth until they freed up. The valve-grinding compound cuts the necessary clearance surprisingly quickly if you clamp the bottom track in a vise and grab one of the welded studs of the upper track in Vise-Grip pliers (suitably cushioned with inserts of plywood, naturally, to avoid ruining the threads) and work the track back and forth in increasing increments.

Steve Wilkinson

|

From "Tool Talk" Falco Builders Letter, December 1986 |

I have recently discovered a sprayable contact cement that is useful for installing upholstery and carpeting. A 3M product, General Trim Adhesive comes in two versions: 08080 is the regular blend and 08090 is the stronger adhesive, and you should be able to get either one at your local auto paint store.

|

January 2001 |

I was just surfing around a bit and found quite a good site with aircraft upholstery tips and I though you might like to link it from your Skunkworks.

http://www.bitchin-stitchin.com/trimtips.htm

George Richards

|

|