Wing Leading Edge Skins

![]()

Wing Leading Edge Skins |

|

|

From "Mailbox" Falco Builders Letter, December 1996 |

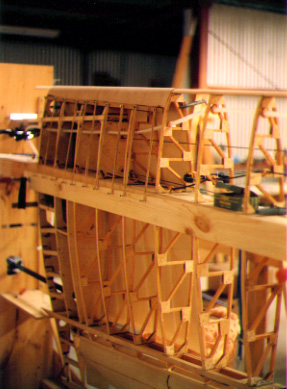

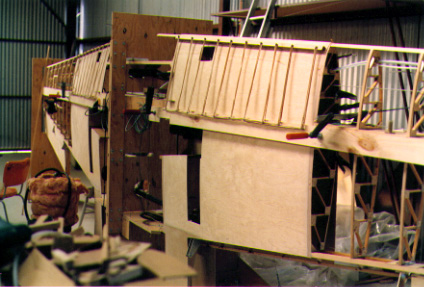

I enclose some photos of my Falco project. Some are of the process of bending the plywood for the wing leading edge. The trough and immersion heater were used to boil the leading edge of the plywood prior to bending. The bending itself was done with ordinary office-type rubber bands attached at the plywood end to wire hooks through holes in the plywood and at the spar end to screws in a board clamped to the spar. The innermost panels had extra wood glued to the leading edges but this was not necessary further out. With the further aid of a steamer, the plywood practically fell around the leading edge.

Ian Ferguson

Wood trough to take the leading edge of the skins for soaking and boiling.

Note immersion heater.

Ian is apparently directing steam to the leading edge skin.

The skin is clamped in place with Hansen-style rubber bands.

Now the top skin goes on.

And a skin toward the wing tip.