Dave Gauger's Scarfing Jig

![]()

Dave Gauger's Scarfing Jig |

|

by Dave Gauger

|

This article appeared in the June 1988 Falco Builders Letter. |

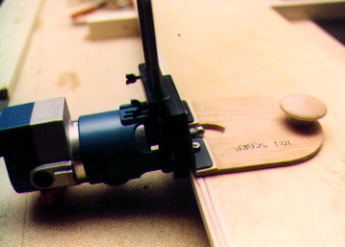

The router is set to a 10:1 slope and uses a laminate trimmer bit.

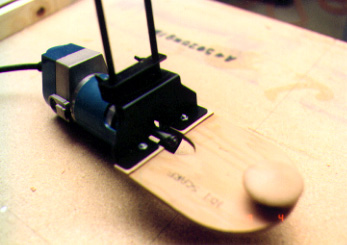

The scarfing jig I've devised may be the simplest and cheapest method I've come across so far. I began by taking a Ryobi TRU 30 laminate trimmer. When I bought this laminate trimmer several years ago, it was being promoted as a baby router and came with an edging attachment. I find that the laminate trimmer, when used with a straight bit with a pilot wheel on the end is the ideal tool for trimming aircraft plywood without it splintering. The edging adapter is basically a metal flange that is perpendicular to the base of the router and parallel to the cutting edge of a straight cutter, that allows you to precisely control the depth of the cut.

I have been making 10 to 1 scarf joints, so I took a piece of scrap 1/4" plywood and glued to one end of it a strip of aircraft plywood that had been scarfed by hand to 10 to 1. I bolted this to the flange of the edging adapter. This tips the laminate trimmer so that it cuts with a 10 to 1 slope. I use a Bosch 3-flute router bit with a pilot wheel on one end, which I chose because it has cutting surfaces that are over an inch long.

To use this contraption, I take the board that is going to be scarfed and measure how wide the scarf joint ought to be. I adjust the depth of the router bit to the width of the scarf joint, and adjust the depth of the cut up or down until the pilot wheel just barely contacts the surface of the board being scarfed.

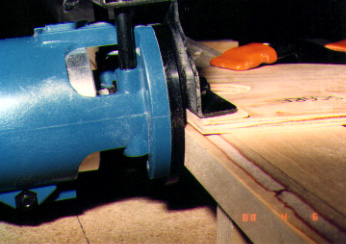

Basically what I've created is a narrow motorized plane that is tipped so it cuts a 10 to 1 slope. Because the edge of the plywood becomes fairly flimsy as you cut it, I clamp the entire piece of plywood that I am scarfing to a piece of scrap one-by-four so that the router base has something solid to bear against. Because the router base is tipped 5.7° from perpendicular (the arc tangent of 10/1 is 5.7°), I have beveled the edge of the one-by-four so that the fit is better.

Using this setup, I scarfed the four panels for my elevator in about 20 minutes one evening, after first making two passes on some scrap plywood. It seems to work better if you cut from right to left with this particular router combination. You can decide what slope you want to use for your scarf joints by simply changing the slope of the shims between the edger and the scrap piece of 1/4" plywood.