Craig Bransfield

![]()

Craig Bransfield |

|

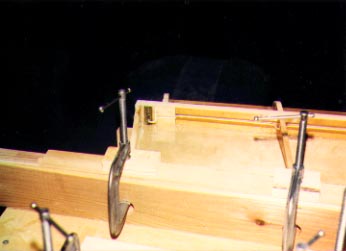

The jig supports planed to proper height/angle to assure correct 'twist'.

Vent/drain holes drilled. Ready to varnish interior.

Flap/Aileron interior varnished and float-sanded.

The cross members on the top *1" x 2") with long threaded rods provide adjustable downward pressure to overcome the tension of installed low skins. Nothing yet on the top to counterbalance the tension. (To explain, Craig is following the theory of slightly dampening the skins when you glue them in place, so that they will be under a slight tension and therfore will result in smoother skins.)

Ground wiring connecting channel-nuts in the flaps and ailerons.

The wire is simply 'painted into the corner' with West System epoxy.

Go back to Wing